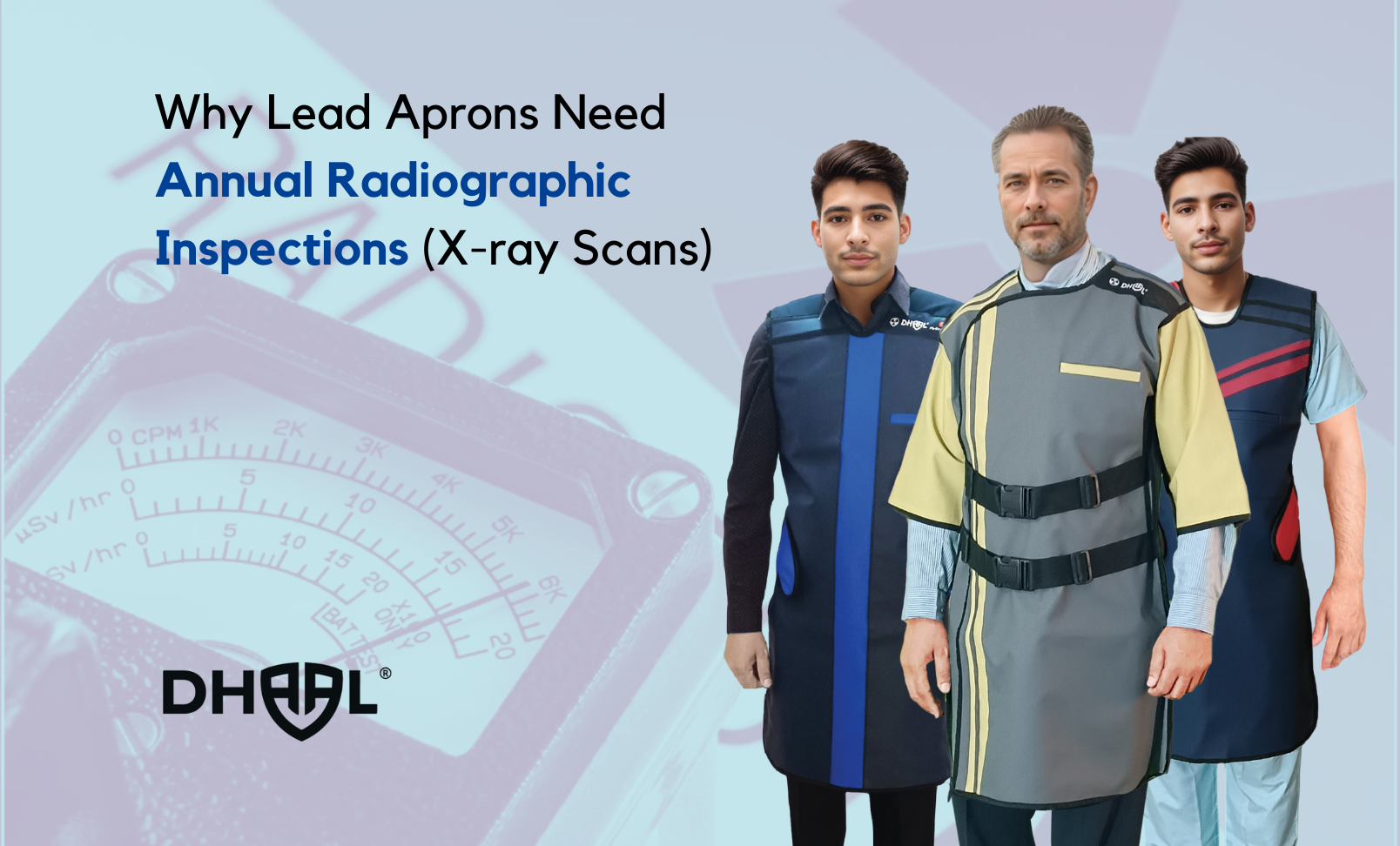

Lead aprons are essential in protecting medical professionals from radiation exposure, but their effectiveness can diminish over time due to wear and tear. Annual radiographic inspections (X-ray scans) are crucial to ensure these aprons maintain their protective qualities. Here’s why these inspections are necessary:

1. Wear and Tear Detection

• Description: Lead aprons are subjected to physical wear and tear from regular use, storage, and handling. This wear can cause cracks, tears, or other damage to the apron’s lead lining or outer fabric.

• Importance of Inspection: Annual radiographic inspections help identify any damage that might not be visible to the naked eye. Cracks or defects in the lead lining can compromise the apron’s effectiveness in shielding against radiation.

2. Maintaining Radiation Protection Standards

• Description: The primary function of lead aprons is to shield against ionizing radiation. Over time, the protective lead layer may become less effective due to damage or degradation.

• Importance of Inspection: X-ray scans can verify whether the apron still meets the required standards for radiation attenuation. This ensures that the apron continues to provide adequate protection for medical professionals.

3. Compliance with Safety Regulations

• Description: Regulatory agencies and health and safety standards often require regular checks to ensure radiation protection equipment is functioning correctly.

• Importance of Inspection: Conducting annual inspections helps facilities comply with legal and safety regulations, reducing the risk of non-compliance penalties and ensuring a safe working environment.

4. Identifying Wear in High-Stress Areas

• Description: Certain areas of the apron, such as around the shoulders and waist, may experience more stress and potential damage due to frequent movement and handling.

• Importance of Inspection: Radiographic inspections can reveal wear in these high-stress areas that might compromise protection. Identifying these issues early allows for timely repairs or replacements.

5. Extending the Lifespan of Aprons

• Description: Regular inspections help in maintaining the condition of the aprons, potentially extending their useful lifespan.

• Importance of Inspection: Early detection of issues allows for repair or replacement before the apron becomes ineffective, maximizing its longevity and protecting the investment made in quality protective gear.

6. Preventing Radiation Exposure Risks

• Description: Any compromise in the apron’s integrity could result in increased radiation exposure for medical professionals, which can have long-term health implications.

• Importance of Inspection: Regular checks ensure that the aprons are always in optimal condition, preventing potential exposure risks and safeguarding the health of healthcare workers.

7. Quality Assurance

• Description: Ensuring the quality and reliability of radiation protection equipment is vital for maintaining trust in its effectiveness.

• Importance of Inspection: Routine inspections provide a level of quality assurance, confirming that the aprons are performing as expected and continue to offer reliable protection.

8. Enhancing Facility Safety Protocols

• Description: Incorporating regular inspections into safety protocols demonstrates a commitment to maintaining high safety standards and protecting personnel.

• Importance of Inspection: It supports a culture of safety within the facility and reinforces the importance of using well-maintained protective equipment.

How Radiographic Inspections Are Performed

1. X-ray Scanning: The apron is subjected to X-ray scans to detect any abnormalities or degradation in the lead lining.

The scans reveal any areas where the lead may have become thin, damaged, or compromised.

2. Visual and Physical Inspection: Alongside X-ray scans, a thorough visual and physical inspection is conducted to check for any visible damage or signs of wear on the apron’s outer material.

3. Documentation and Reporting: The results of the inspection are documented, and any issues are reported. This documentation is important for compliance and tracking the condition of the aprons over time.

4. Repair or Replacement: Based on the inspection results, aprons may be repaired or replaced as needed to ensure they continue to meet radiation protection standards.

Conclusion

Annual radiographic inspections of lead aprons are a critical practice for ensuring the ongoing effectiveness and safety of these essential protective garments. By identifying and addressing issues early, facilities can maintain high standards of radiation protection, comply with regulations, and safeguard the health and well-being of their medical staff.